ABB AC Servo Drives

ABB AC Servo Drives Specification

- Working Temperature

- 0C to +50C

- Output Type

- Analog / Digital

- Current Range

- 2A to 160A

- Phase

- Three Phase

- Rated Current

- Varies by model

- Application

- Industrial Automation, Robotics, CNC Machines, Material Handling

- Power Supply

- AC Mains Supply

- Noise Level

- < 65 dB

- Rated Power

- 400W to 90kW

- Cooling Method

- Forced Air Cooling

- Connector Type

- Screw Terminals / Pluggable connectors

- Features

- High precision control, Modbus/Fieldbus compatibility, Compact design

- Power Factor

- >0.95

- Output Current

- 1.7A to 160A (model dependent)

- Operating Temperature

- 0C to +45C

- Product Type

- AC Servo Drive

- Output Power

- 0.4 kW to 90 kW (varies by model)

- Output Frequency

- 0-600 Hz

- Input Voltage

- 200-240V AC / 380-480V AC (three-phase, model dependent)

- Voltage Protection

- Overvoltage, Undervoltage, Surge protection

- Efficiency

- Up to 98%

- Material

- Industrial Grade Metal Enclosure

- Line Regulation

- < 0.5%

- Storage Temperature

- -20C to +65C

- Weight

- Approx. 2.5 kg to 25 kg (varies by model)

ABB AC Servo Drives Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Middle East

- Main Domestic Market

- All India

About ABB AC Servo Drives

Features:

- Variety control modes

- Excellent performance

- Seamless operation

- Wide range of speed and current

High-Precision Performance

Designed for superior accuracy, ABB AC Servo Drives provide high-precision control for torque, position, and speed, making them ideal for robotics, CNC machinery, and automation systems. Their Modbus/RS-485 communication ensures easy integration into modern industrial networks while the digital LED display offers convenient real-time monitoring and adjustments.

Robust Design and Safety Features

Housed in industrial-grade metal with an IP20 enclosure rating, these drives offer exceptional durability and protection. Integrated protectionsovervoltage, undervoltage, and surgeensure safe and stable operation. Multiple cooling and vibration-resistant features further enhance reliability and extend the drives service life to over 10 years.

Flexible Installation and Wide Compatibility

Panel mount design with screw terminals or pluggable connectors allows straightforward installation. Supporting input voltages from 200-240V AC and 380-480V AC (three-phase), these drives cater to diverse industrial power requirements and can be easily incorporated into new or existing automation environments.

FAQs of ABB AC Servo Drives:

Q: How are ABB AC Servo Drives typically installed in an industrial setting?

A: ABB AC Servo Drives are panel-mountable, designed for easy installation onto control cabinets or panels. The drives utilize screw terminals or pluggable connectors for secure electrical and signal connections, making the setup process efficient for industrial automation professionals.Q: What benefits does the RS-485/Modbus communication interface offer?

A: The RS-485/Modbus interface enables seamless integration into modern fieldbus systems, facilitating remote configuration, real-time monitoring, and enhanced interoperability with a broad range of industrial controllers and PLCs.Q: When should regenerative braking be used in these servo drives?

A: Regenerative braking is beneficial during rapid deceleration or frequent start-stop operations. It supports efficient energy recovery, reduces heat buildup, and prolongs the service life of both the drive and connected motors.Q: Where can ABB AC Servo Drives be deployed for maximum efficiency?

A: These drives are best used in sectors such as industrial automation, robotics, CNC machinery, and material handling, where high-precision motion control, reliability, and efficiency are essential.Q: What process ensures the safety and reliability of these servo drives?

A: ABB AC Servo Drives incorporate built-in protections against overvoltage, undervoltage, and surges, complemented by robust insulation and forced air cooling. These measures ensure safe operation even under challenging industrial conditions.Q: How does high efficiency and power factor benefit industrial operations?

A: With up to 98% efficiency and a power factor greater than 0.95, these drives minimize energy losses and reduce operational costs, making them a cost-effective choice for large-scale and energy-intensive manufacturing processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Servo Drives Category

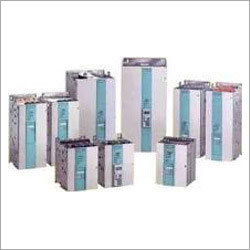

Siemens Intelligent Servo Drives

Minimum Order Quantity : 100 Units

Material : Industrial Grade Metal Enclosure

Efficiency : Up to 98%

Input Voltage : 230V / 400V AC

Application : CNC Machines, Robotics, Packaging, Textile Automation

Rated Power : Variable by model

Siemens AC Servo Drives

Minimum Order Quantity : 100 Units

Material : Industrial Grade ABS/Metal Housing

Efficiency : >= 95%

Input Voltage : 200480V AC, 3Phase

Application : Automation, Robotics, CNC, Packaging, Textile Machines

Rated Power : Up to 132 kW

Siemens DC Servo Drives

Minimum Order Quantity : 100 Units

Material : Industrialgrade Alloy and ABS Housing

Efficiency : Up to 98%

Input Voltage : 24 VDC 440 VDC

Application : Automation, CNC Machines, Robotics, Industrial Drives

Rated Power : Depends on model (0.5 kW, 5.5 kW, 15 kW, etc.)

FX 2000 Flexi Series AC Drives

Material : ABS/Metal Enclosure

Efficiency : Up to 98%

Input Voltage : 415V AC 10%, 3 Phase

Application : Pumps, fans, conveyors, HVAC, compressors, general automation

Rated Power : 0.75 kW to 500 kW

Send Inquiry

Send Inquiry