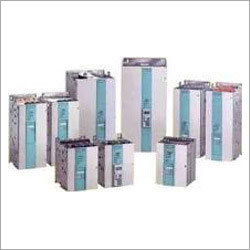

Siemens DC Servo Drives

Siemens DC Servo Drives Specification

- Rated Power

- Depends on model (0.5 kW, 5.5 kW, 15 kW, etc.)

- Application

- Automation, CNC Machines, Robotics, Industrial Drives

- Features

- High Precision, Compact Design, Fast Response, Integrated Protection

- Connector Type

- Screw Terminals / Plug connectors

- Working Temperature

- 0C to 55C

- Phase

- Single Phase / Three Phase

- Output Type

- Analog / Digital

- Current Range

- 0.2A 200A

- Noise Level

- < 55 dB

- Output Current

- 0.2A 175A

- Power Factor

- > 0.95

- Operating Temperature

- 0C to 55C

- Rated Current

- Varies per model

- Power Supply

- DC

- Cooling Method

- Forced Air Cooling

- Product Type

- DC Servo Drive

- Output Power

- 0.5 kW 90 kW

- Output Frequency

- 0 400 Hz

- Input Voltage

- 24 VDC 440 VDC

- Voltage Protection

- Overvoltage and Undervoltage Protection

- Efficiency

- Up to 98%

- Material

- Industrial-grade Alloy and ABS Housing

- Line Regulation

- 1%

- Storage Temperature

- -20C to 70C

- Weight

- 6 kg 25 kg

- Adjustable Parameters

- Speed, Torque, Ramp Up/Down Time

- Display

- LCD / LED Status Indicators

- Protection Features

- Short Circuit, Overload, Over-temperature

- Communication Interface

- RS232 / RS485 / CANopen / EtherCAT

- Mounting Type

- Panel Mount / DIN Rail

- Motor Supported

- DC Servo Motor

- Response Time

- < 1 ms

- Startup Time

- < 2 seconds

- IP Rating

- IP20 / IP40 (varies by model)

- Humidity Range

- 5% to 95% non-condensing

- Insulation Class

- Class F

- Vibration Resistance

- 2.5G

- Control Method

- PWM (Pulse Width Modulation), Vector Control

Siemens DC Servo Drives Trade Information

- Minimum Order Quantity

- 100 Units

- Payment Terms

- Cheque

- Supply Ability

- Unit

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Middle East

- Main Domestic Market

- All India

About Siemens DC Servo Drives

Features:

- Robust construction

- Negligible maintenance

- Finest quality

- Excellent performance

Advanced Control and Communication Capabilities

Benefit from PWM and vector control technology, ensuring high precision in speed and torque adjustments, ideal for demanding automation scenarios. Multiple communication interfaces, including RS232, RS485, CANopen, and EtherCAT, make system integration flexible for manufacturers and solution providers.

Rugged Design and Reliable Operation

Siemens DC Servo Drives are constructed with industrial-grade alloys and ABS housing, and offer operation within 0C to 55C, a humidity range up to 95%, and vibration resistance up to 2.5G. Their IP20/IP40 enclosure ratings help ensure durability in various industrial environments.

Intuitive Monitoring and Comprehensive Protection

With LCD or LED status indicators, monitoring operational status is straightforward. Integrated protection mechanisms guard against short circuits, overloads, over-temperature, undervoltage, and overvoltage, supporting continuous and safe industrial productivity.

FAQs of Siemens DC Servo Drives:

Q: How do Siemens DC Servo Drives provide high precision in motor control?

A: Siemens DC Servo Drives utilize Pulse Width Modulation (PWM) and vector control methods, enabling accurate adjustment of speed, torque, and ramp settings. These features ensure optimal performance and repeatability in applications like robotics and CNC machines.Q: What communication interfaces are supported by these drives for system integration?

A: These drives offer a range of communication options including RS232, RS485, CANopen, and EtherCAT, allowing easy integration with existing industrial control systems, PLCs, and automation networks.Q: When is Siemens DC Servo Drive protection activated, and what does it cover?

A: The drives protection features activate upon detecting issues such as short circuits, overloads, over-temperature, overvoltage, or undervoltage. This helps safeguard both the drive and connected motor, reducing the risk of operational downtime.Q: Where can these servo drives be mounted within an industrial environment?

A: Siemens DC Servo Drives are suitable for both panel and DIN rail mounting, offering flexible installation options according to space and system design requirements in varied industrial settings.Q: What are the main advantages of using Siemens DC Servo Drives in automation and industrial applications?

A: Key benefits include fast response times (<1 ms), high efficiency (up to 98%), compact design, integrated protection features, and wide adjustable parameters. These attributes collectively enhance operational reliability, energy savings, and process precision.Q: How does the drive handle varying environmental and operational conditions?

A: Built for industrial environments, the drives perform reliably within a wide temperature range (0C55C), high humidity (up to 95% non-condensing), and moderate vibration ( 2.5G), ensuring consistent performance in demanding conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Servo Drives Category

Siemens AC Servo Drives

Minimum Order Quantity : 100 Units

Efficiency : >= 95%

Output Power : 0.1 kW to 132 kW (range available)

Voltage Protection : Over/Under Voltage Protection

Product Type : AC Servo Drive

Output Type : Other, Three Phase

Bosch AC Servo Drives

Minimum Order Quantity : 100 Units

Efficiency : Up to 95%

Output Power : 400 W to 8 kW (model dependent)

Voltage Protection : Overvoltage, undervoltage, phase loss

Product Type : AC Servo Drive

Output Type : Other, Digital, Analog (model dependent)

LX 2000 Lift Series AC Drive

Efficiency : High efficiency (>90%)

Output Power : 0.75kW 630kW

Voltage Protection : Overvoltage undervoltage protection

Product Type : AC Drive

Output Type : Other, AC output

Siemens AC Servo Drives

Efficiency : High efficiency

Output Power : Range from 0.1 kW to 15 kW

Voltage Protection : Overvoltage and undervoltage protection

Product Type : Siemens AC Servo Drives

Output Type : AC output, Other

Send Inquiry

Send Inquiry